Water Filtration Solutions

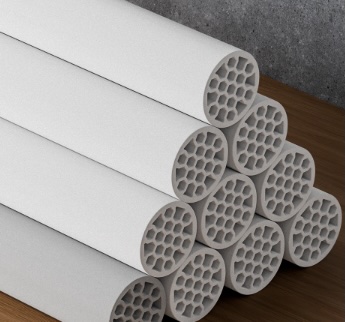

Advanced Ceramic Membrane

Water Treatment Technology

Modern water treatment demands cleaner, safer, and more sustainable solutions. Our ceramic membrane technology delivers exceptional filtration performance with longer service life, lower operating costs, and zero PFAS contamination.

Water Plant Generations

The Evolution of Water Treatment

Water Plant 1.0 — Clean Water

Traditional treatment using coagulation, sedimentation, sand filtration, and chlorination. Meets basic water cleanliness standards.

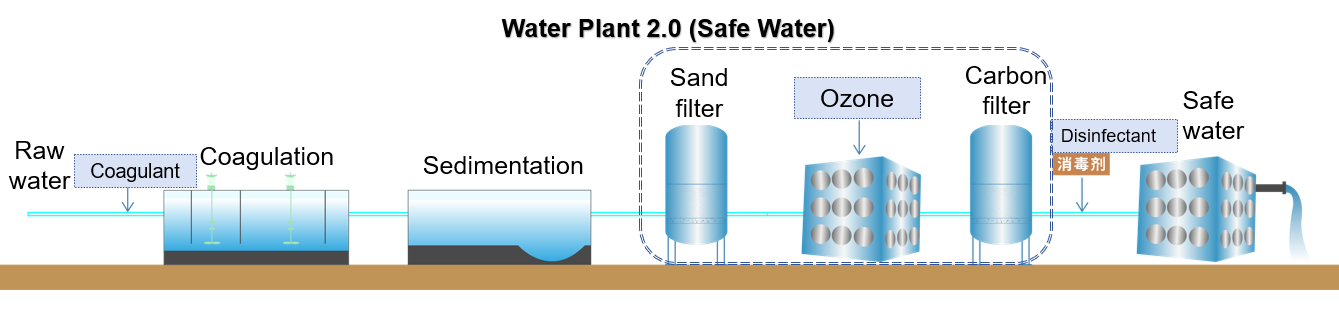

Water Plant 2.0 — Safe Water

Enhanced treatment adding ozone, activated carbon, and ultrafiltration to traditional processes. Removes more contaminants for safer drinking water.

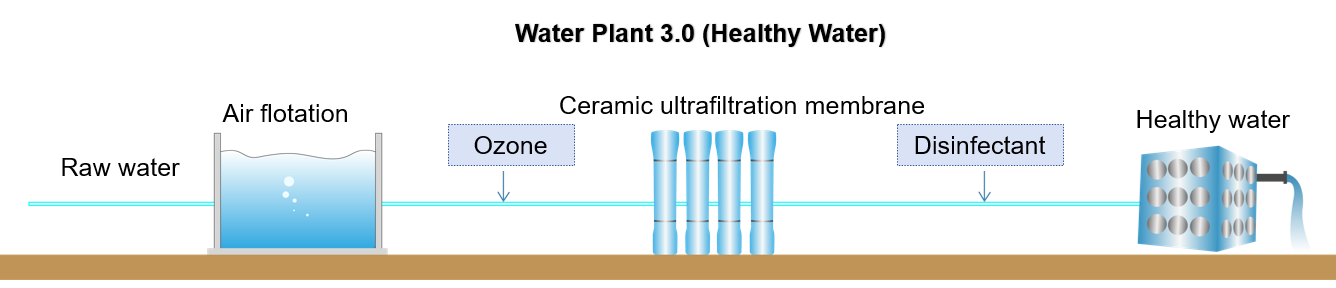

Water Plant 3.0 — Healthy Water

Next-generation treatment using ceramic membrane filtration with integrated ozone and activated carbon. Delivers the highest quality water with fewer chemicals, less footprint, and full automation.

Water Plant 3.0

Advantages of Next-Generation Water Treatment

Ceramic membrane-based water treatment plants offer significant improvements over traditional methods.

Less Chemicals

Ceramic membranes require significantly fewer chemical additives compared to conventional treatment, reducing operational complexity and environmental impact.

Less Footprint

Compact system design reduces the physical footprint by up to 50% compared to traditional water treatment plants of the same capacity.

Better Water Quality

Achieves superior water quality with 30-nanometer filtration precision, effectively removing bacteria, turbidity, and microcontaminants.

Less Labor

Automated operation and reduced maintenance requirements mean fewer staff are needed to operate the plant.

Higher Automation

Fully integrated control systems enable remote monitoring and automated operation, improving consistency and reducing human error.

Shorter Processes

Streamlined treatment processes eliminate multiple traditional steps, reducing treatment time and energy consumption.

Process Comparison

Water Treatment Process Flow

Compare the traditional Water Plant 2.0 process with the streamlined Water Plant 3.0 ceramic membrane approach.

Core Technology

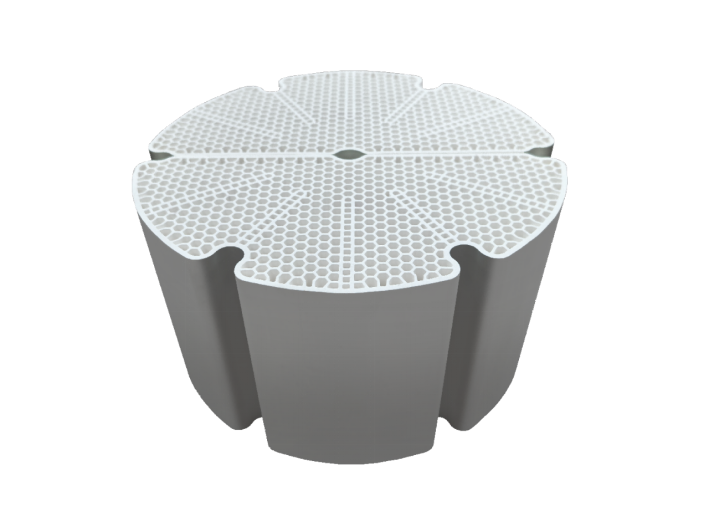

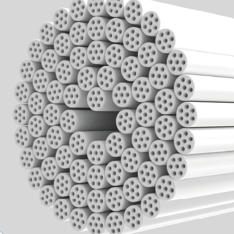

Ceramic Membrane Filtration

What is a Ceramic Membrane?

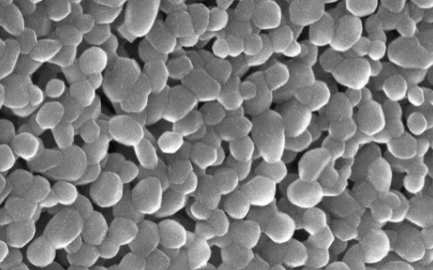

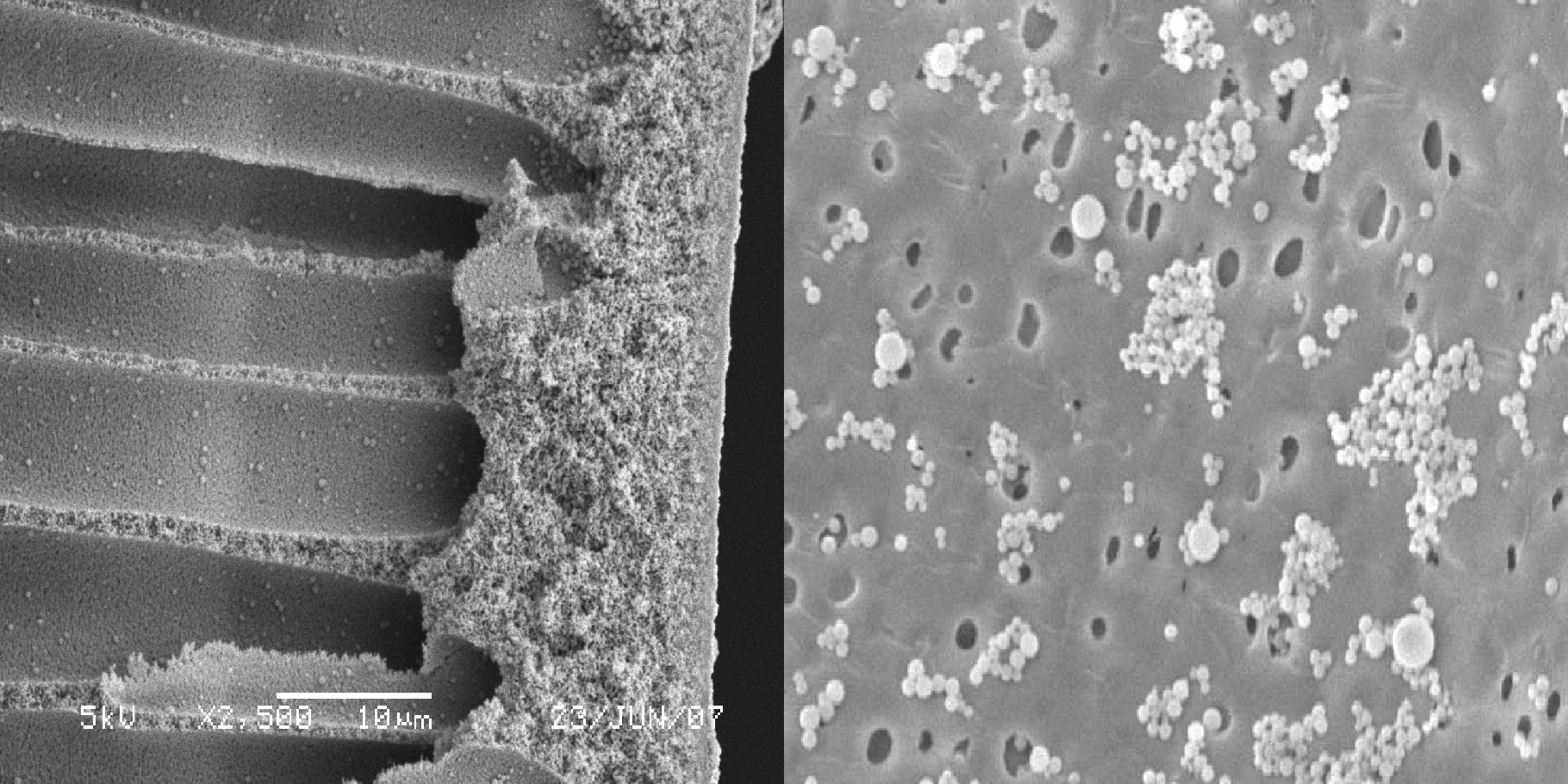

Ceramic membranes are inorganic filtration membranes made from materials such as alumina and zirconia. With a filtration precision of approximately 30 nanometers, they effectively remove bacteria, suspended solids, and microcontaminants while allowing beneficial minerals to pass through.Excellent Mechanical Strength

Ceramic membranes withstand high pressures and aggressive cleaning without degradation, making them ideal for demanding water treatment applications.

Chemical Stability

Resistant to a wide range of chemicals, pH extremes, and oxidizing agents. Compatible with ozone and chlorine-based cleaning processes.

Good Hydrophilicity

The naturally hydrophilic ceramic surface attracts water and repels contaminants, maintaining high flux rates and reducing fouling.

Built to Last

Superior Performance & Sustainability

Designed for Decades of Service

Our ceramic membranes are engineered for exceptional longevity and efficiency, delivering outstanding performance throughout their extended service life.Long Service Life — 20+ Years

Ceramic membranes last over 20 years, far exceeding the 5-8 year lifespan of organic membranes. This dramatically reduces replacement costs and waste.

High Water Recovery Rate — 98%+

Achieve water recovery rates exceeding 98%, minimizing water waste and maximizing the efficiency of your treatment system.

Low Operating Costs

Lower energy consumption, reduced chemical usage, and minimal maintenance combine to deliver significantly lower total cost of ownership.

Fully Recyclable

At end of life, ceramic membranes can be recycled into ceramic products such as tiles and wares, supporting a circular economy.

Safety & Sustainability

PFAS-Free & Environmentally Responsible

Clean Technology for Clean Water

With growing awareness of PFAS contamination in water supplies, ceramic membrane technology offers a fundamentally safer alternative. The inorganic composition ensures no harmful substances leach into your treated water.Zero PFAS Contamination

Unlike organic polymer membranes, ceramic membranes contain no PFAS (per- and polyfluoroalkyl substances), eliminating the risk of "forever chemical" contamination in treated water.

No Microplastic Shedding

Ceramic membranes do not shed microplastics during operation, unlike polymeric alternatives. This ensures your treated water remains free from plastic contamination.

Recyclable at End of Life

Spent ceramic membranes can be ground down and repurposed into ceramic tiles, wares, and other products — unlike organic membranes which go to landfill.

Manufacturing Excellence

Process & Engineering Advantages

Our ceramic membrane products are backed by world-class manufacturing capabilities and engineering expertise.

High-Fill Components

Advanced membrane module designs maximize filtration area within compact housings, delivering high throughput in a small footprint.

Product-to-Engineering Feedback Loop

Continuous feedback between product performance data and engineering design ensures ongoing improvements in membrane quality and durability.

World's Largest Production Line

Our company operates the world's largest ceramic membrane production line, ensuring consistent quality and reliable supply at scale.

Customized Solutions

We provide customized membrane solutions tailored to specific water quality conditions, treatment requirements, and capacity needs.

Equipment Solutions

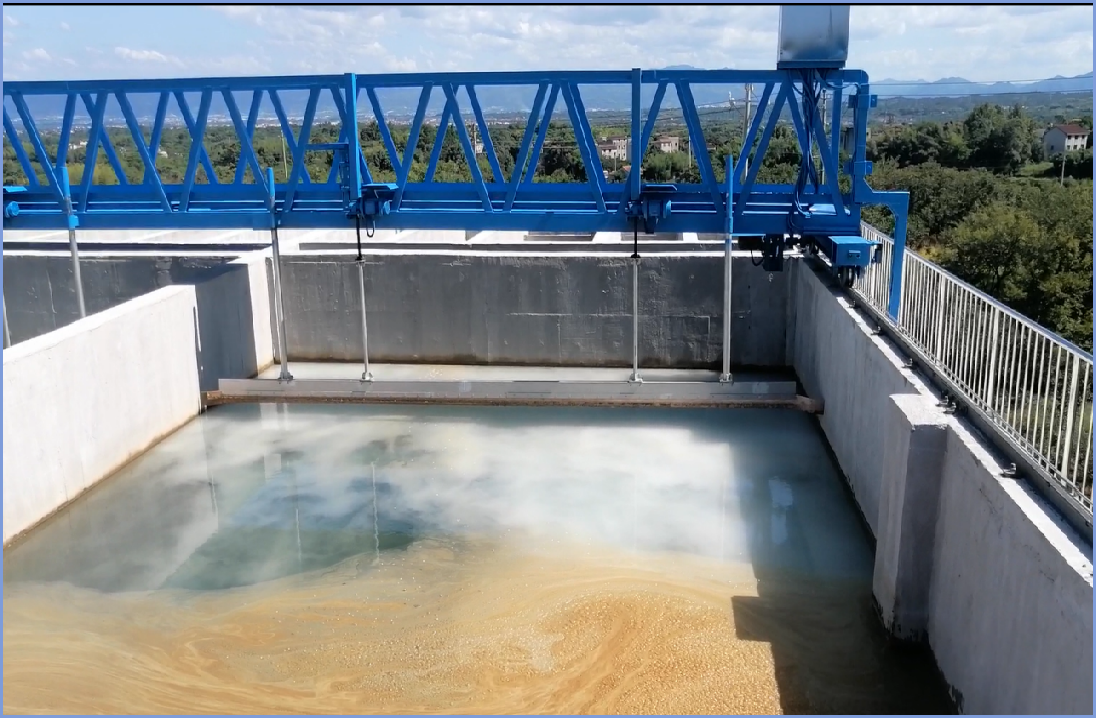

Air Flotation Systems

Advanced Pre-Treatment Technology

Our air flotation systems provide highly effective pre-treatment for ceramic membrane filtration, removing suspended solids and reducing membrane fouling for optimal long-term performance.Efficient Contaminant Removal

Air flotation technology uses micro-bubbles to separate suspended solids, oils, and other contaminants from water, providing effective pre-treatment before membrane filtration.

Integrated Coagulant Dosing

Built-in coagulant generation and dosing systems optimize floc formation for maximum contaminant removal efficiency.

Compact & Modular Design

Our horizontal-flow air flotation units are designed for easy installation and integration with existing water treatment infrastructure.

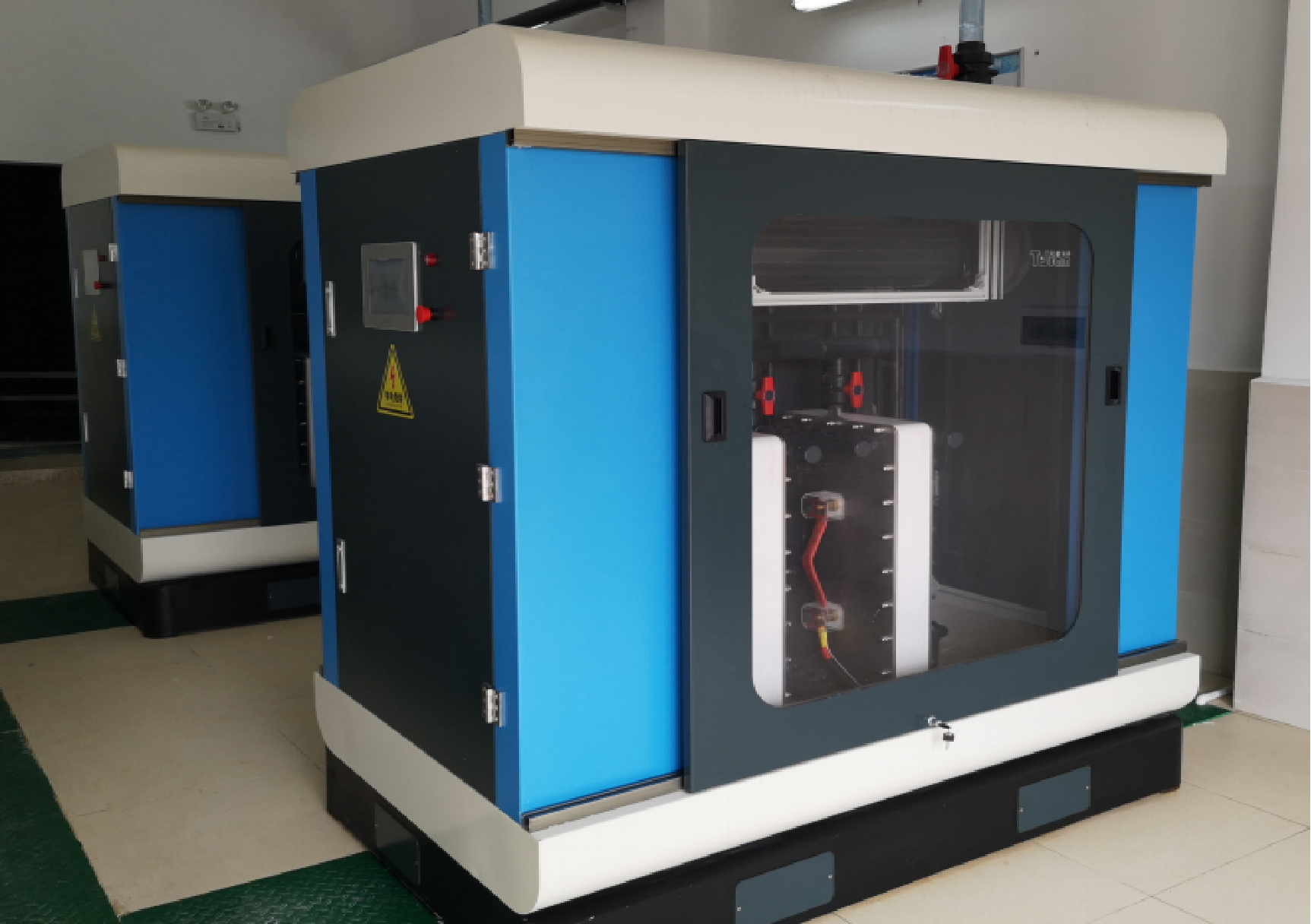

Disinfection Technology

Ozone Water Generator

Clean & Effective Disinfection

Our ozone water generators provide chemical-free disinfection that complements ceramic membrane filtration, delivering comprehensive water treatment without harmful by-products.Powerful Oxidation

Ozone is one of the strongest oxidants available for water treatment, effectively destroying bacteria, viruses, and organic contaminants.

No Chemical Residuals

Ozone naturally decomposes back to oxygen, leaving no harmful chemical residuals in treated water — unlike chlorine-based disinfection.

Taste & Odour Removal

Ozone oxidation eliminates taste and odour compounds, producing cleaner and fresher-tasting water.

On-Site Generation

Sodium Hypochlorite Generator

Safe & Reliable Disinfection

Our sodium hypochlorite generators produce disinfectant on-site, providing a safer alternative to transporting and storing concentrated chemicals while ensuring continuous availability.On-Site Chemical Generation

Generate sodium hypochlorite on-site from salt and water, eliminating the need for hazardous chemical transport and storage.

Consistent Concentration

Automated systems maintain precise hypochlorite concentration for reliable and consistent disinfection performance.

Cost-Effective Operation

On-site generation significantly reduces chemical procurement costs and eliminates supply chain dependencies.

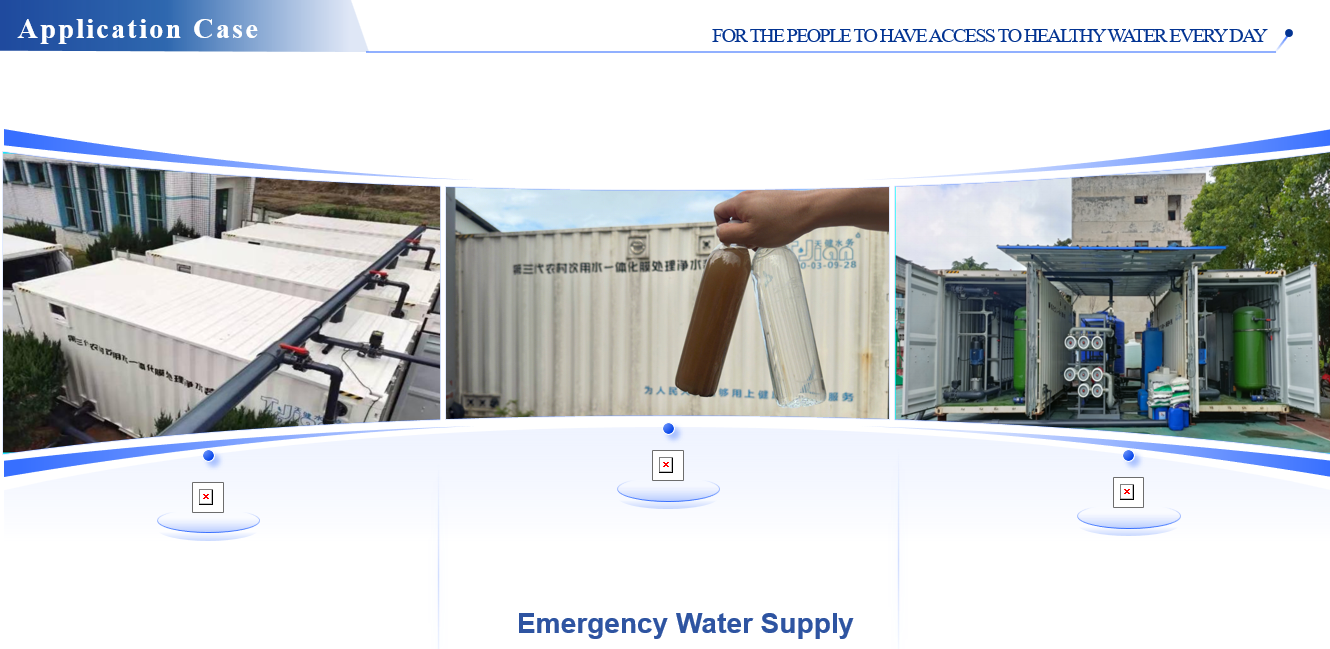

Application Cases

Real-World Applications

Our ceramic membrane water treatment technology is deployed across a wide range of applications worldwide.

Ready to Upgrade Your Water Treatment?

Whether you need ceramic membrane filtration systems, air flotation pre-treatment, or complete water treatment solutions, we have the expertise to help. Contact us to discuss your requirements.